The Technology That Gives Rimblades The Edge

Jun 29, 2020

Our new and improved 2020 product range launched back in March and is the culmination of a decade of customer feedback, intensive research, testing and development supported by the UK 3M laboratory. The new Rimblades range – consisting of Rimblades Light, Ultra and Pro utilise some of the very best technologies available today.

Here is a deeper dive into some of the key technologies behind our products, based on our mid-range (and most popular ‘Blade), the Rimblades Ultra.

3M Bonding Technology

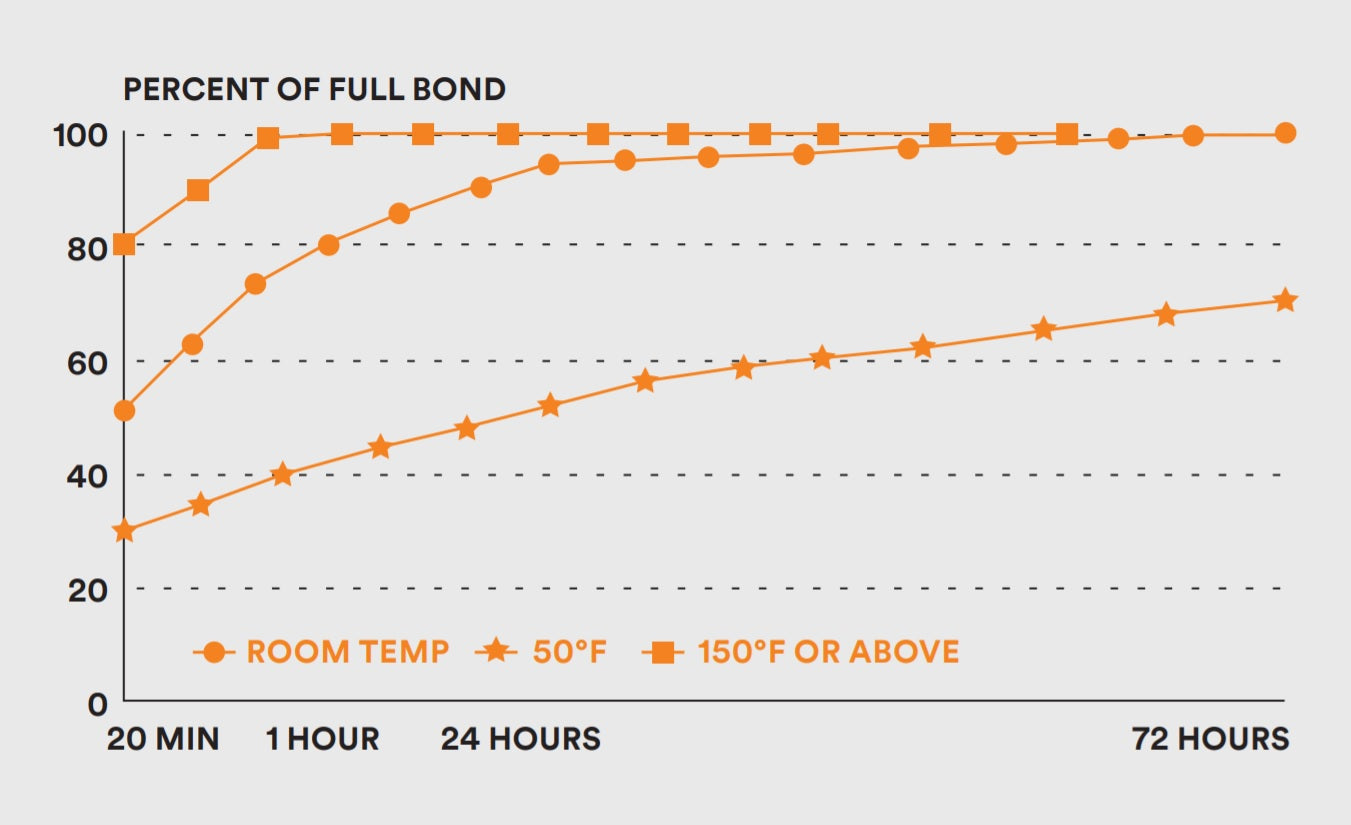

3M bonding technology is utilised within a wide range of high-tech sectors and applications, from automotive, aerospace and fabrication to electronics and nautical. The 3M VHB tape that we use creates an incredibly strong, durable and consistent bond. For those who think this is just any old sticky backed tape – think again. Being virtually invisible it is a highly technical solution which adheres using viscous flow, and achieves maximum bond at 72 hours.

Credit: www.3m.co.uk

3M bonding technology withstands extreme heat, cold, vibration, moisture and UV light – adverse conditions often encountered when driving at the limits. In addition to the independent testing and approvals gained by 3M, Rimblades have also been proven by world renowned automotive testers, Millbrook. The product has even passed stringent manufacturer OE testing involving a 10,000 KM continual endurance test.

Why use bonding technology?

As a bond-on upgrade, there are several major advantages over traditional ‘tyre trapped’ type rim protectors. Firstly, there are no rigid parts to cause wheel damage. Because of the sealed bond there is also none of the damage caused by dirt and grit getting underneath the protector and effectively ‘sanding’ the wheel surface as the protector moves between tyre bead and rim. Secondly, the tyre bead isn’t compromised. Bead integrity is critically important for the enthusiast, as during spirited drives, or at the track, tyres naturally move around more against the wheel due to the higher forces generated. Additionally, there is the possibility of air escaping past a tyre trapped protector, which is undesirable from both a performance and safety perspective. Worse, the chance of blow-out deflation could cause a tyre trapped protector to suddenly detach and rotate at very high speed – doing serious damage to wheel, arch and bodywork.

VHB removal solution

A huge benefit with Rimblades is that the 3M VHB bonding process can be completely reversed using our special VHB removal solution. This not only makes DIY renewal quick and easy (if you damage one of your ‘Blades, or fancy a colour change, for example) but is also perfect for drivers of leased cars, as alloys are left in pristine original condition after removal. No marks, no residue – no sign the product had ever been fitted.

Santoprene TPV

Santoprene TPV (Thermoplastic Vulcanizate) is a premium raw material which costs triple that of the cheaper materials used by the others. But we insist on using it. Here’s why…

Santoprene TPV is a high-performance elastomer manufactured by Exxon Mobil which is probably best described as a plastic that looks and feels like rubber. Santoprene TPV offers reduced weight, increased durability, and most importantly for our products – superior, consistent performance.

It should be noted that although we utilise expensive premium grade, high tech materials such as this, our products retail at around a quarter of the price of some other rim protectors.

Wire Core Technology

Rimblades feature a thin wire core that runs through the centre of the ‘Blade. This is designed to maintain the structural integrity of the profile and prevent the wheel rim protector from ever stretching or shrinking due to extreme hot or cold temperatures.

Get The Edge

If you are a driving enthusiast looking for the smarter way to protect your alloy wheels, we’ve got you covered. Rimblades also deliver a distinctive style upgrade, and as you have just read, a real technical and performance advantage over anything else in the marketplace.